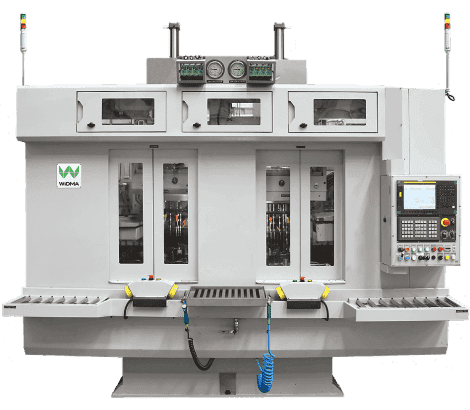

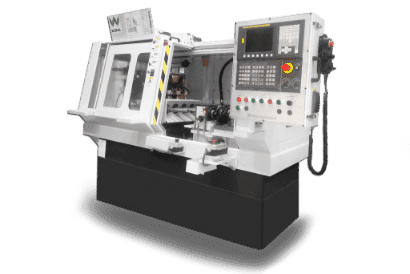

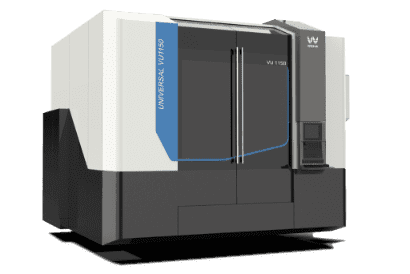

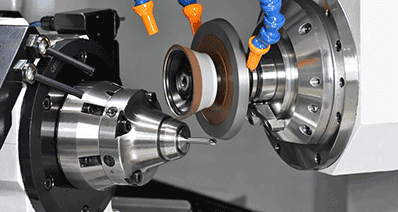

VM SERIES – TOOL SPINDLE TYPE TURN-MILL CENTERS

What Are Tool Spindle Type Turn-Mill Centers

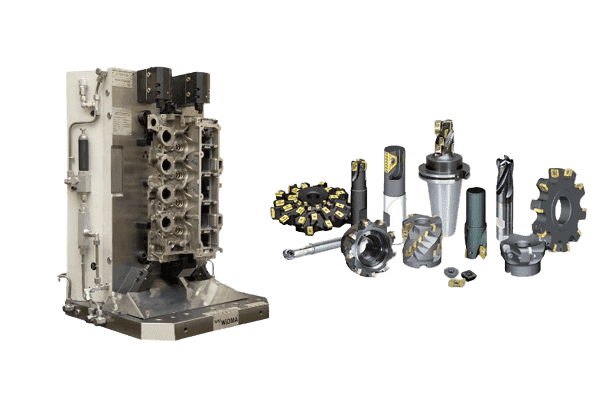

Tool Spindle Type Turn-Mill Centers are advanced multitasking machine tools designed to perform turning, milling, drilling, and tapping operations efficiently and accurately in one setup. The machine combines the functionality of lathe and milling, with a tool spindle type acting as the powerful milling head when in the horizontal position. The spindle holder can also secure turning tools and can thus act as a lathe. It can process parts using turned and stationary tools, helping it machine complicated parts out of a single block of material without manufacturing in multi-setups or transferring to different machines.

The principal ability of these centers is the tool spindle’s capability to move in multi-axes. They usually feature at least 5-axis capability: X, Y, and Z for linear movements and further rotational axes (for example, B and C) that are actually required for the spindle orientation. This versatility allows for the machining of complex geometries and surfaces that would otherwise require specialized machines. This, in turn, becomes the highly flexible machining solution adjustable to a complete scope of manufacturing needs.

Benefits of Tool Spindle Type Turn-Mill Centers

Enhanced Precision and Flexibility

Multi-tasking not only means turning and milling on the same machine; it also reduces the likelihood of errors resulting from repositioning a workpiece from one machine to another. It assures better precision and repeatability across various parts. The multi-axis machiner, with its ability to cut even the most intricate contours and features, facilitates this without affecting precision or speed.

Reduced Processing Time and Cost

With tool spindle type turn-mill centers, several processing steps are combined into a single process. This eliminates the need for an array of setups and multiple machine transfers, thus drastically reducing processing time. Savings with regard to production time, labor, and running costs are affected, therefore making the entire system of production very economical in nature.

Versatility in Machining

These centers are capable of handling a wide range of materials and part sizes, making them suitable for various industries, from aerospace and automotive to medical and precision engineering. The flexibility to quickly switch between turning and milling operations without changing the setup also allows for short production runs and custom parts manufacturing with minimal downtime.

Improved Surface Finish and Part Quality

Integrated turning and milling capabilities enable components to be finished to high quality with excellent surface finishes. The continuous control of the machining process ensures tighter tolerances and higher quality outcomes in compliance with stringent requirements from industries that demand precision and reliability.

Space and Cost Efficiency

Combining the functions of multiple machines into one, tool spindle type turn-mill centers save valuable floor space in manufacturing facilities. This multifunctionality also means lower initial investment in machinery and reduced maintenance costs over time, making it a cost-effective solution for both small workshops and large manufacturing plants.

Technical Specifications

| Features | Unit |

|

|||

| Machine Capacity | |||||

| Maximum turning diameter | mm |

|

|||

| Standard turning diameter | mm |

|

|||

| Swing Over Bed | mm |

|

|||

| Maximum turning height | mm |

|

|||

| Maximum weight of the job inclusive of chuck | Kg |

|

|||

| Work spindle | |||||

| Power (Continuous | 30 min.) | kW |

|

|||

| Live Spindle (BT50) | |||||

| Power (Continuous | 30 min.) | kW |

|

|||

| Maximum RPM | RPM |

|

|||

| Axis | |||||

| Construction |

|

||||

| Tool station | |||||

| Type |

|

||||

| No. of tools (Std. | Optional) | No. |

|

|||

| Weight (approx.) | Kg |

|