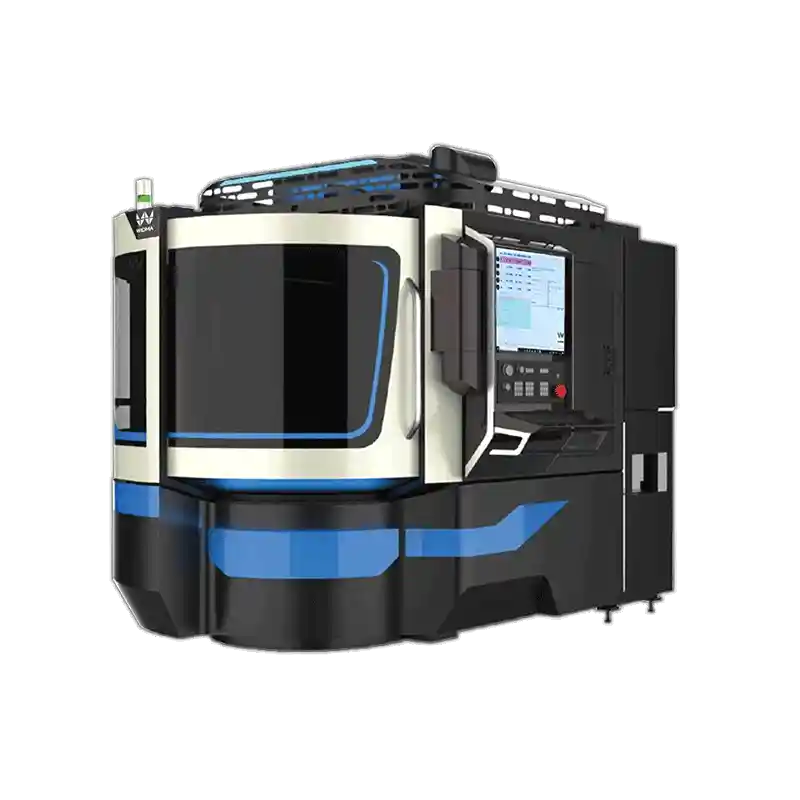

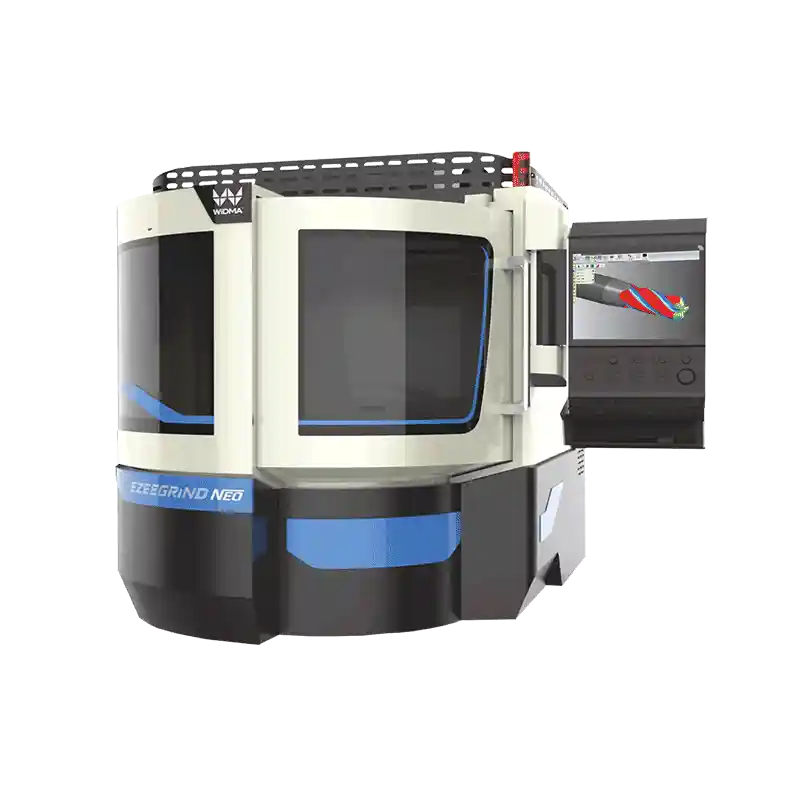

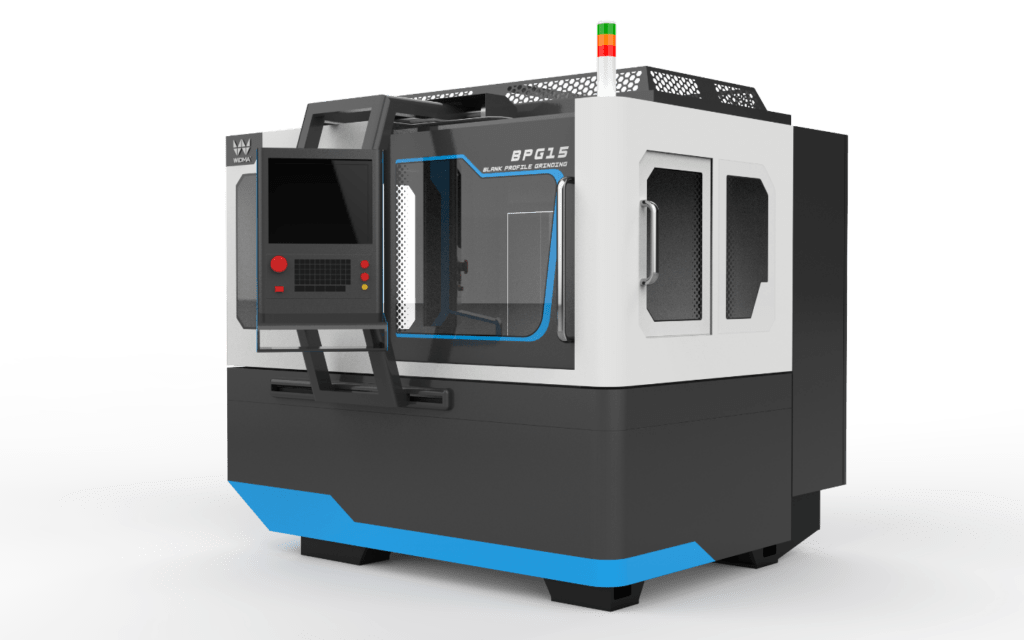

TOOL GRINDING MACHINES

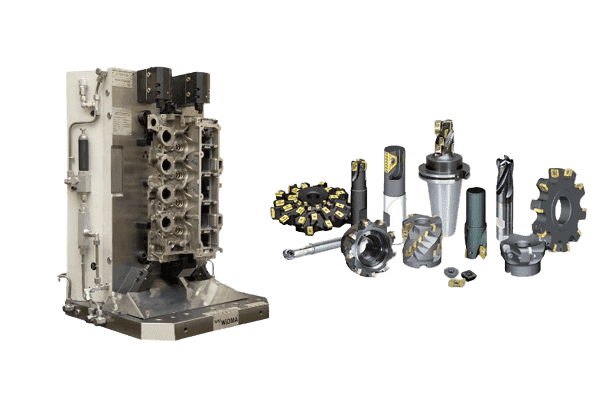

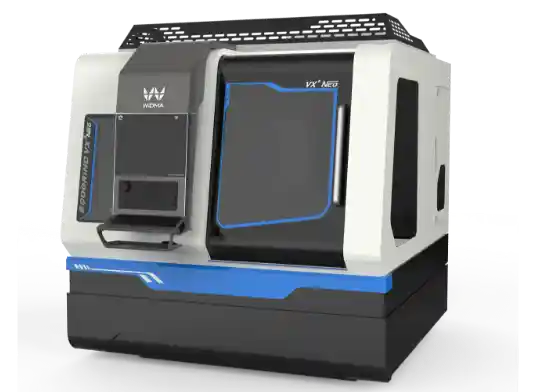

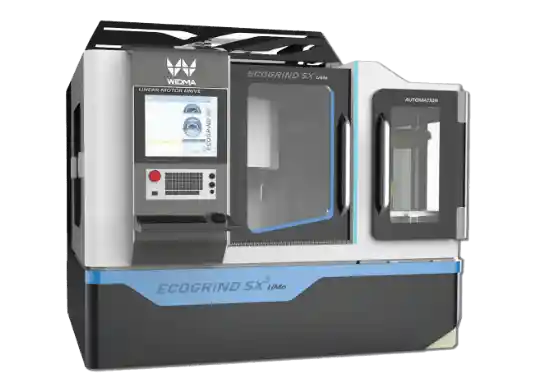

WIDMA’s versatile and highly productive five-axes CNC tool and cutter-grinding machines are the preferred choice for customers across the globe. Suitable for both manufacturing and regrinding of round tools, these machines operate using powerful menu-driven software for grinding complex tool geometries. WIDMA can manufacture tools from 0.3mm up to 32mm, which covers majority of the round tools used for machining. These unique features, backed by the technical expertise of our team has helped us spread our footprint progressively to over 350 installations across different geographies.

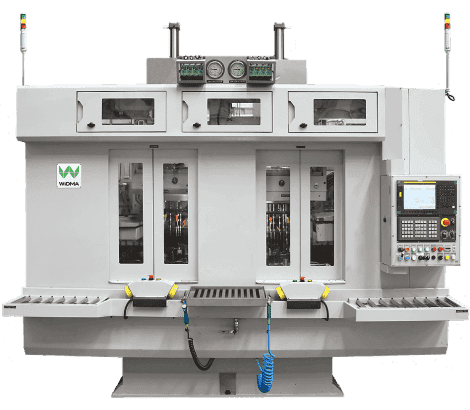

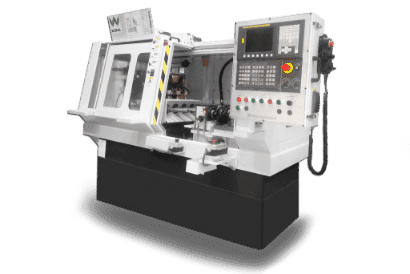

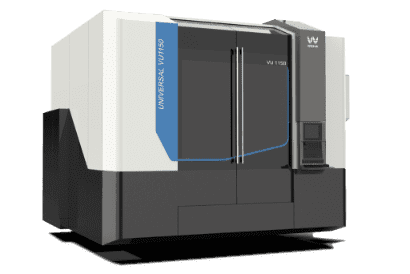

WIDMA’s tool grinding machine portfolio consists of the Ecogrind series, the Ezeegrind series and the Hobgrind series. The Ecogrind series is designed with premium features to deliver best-in-class productivity and versatility. The Ezeegrind series of machines is suited for mass manufacturing, the regulation of standard tools, and selecting complex tools. The Hobgrind series is ideal for resharpening of hob cutters that are used for gear manufacturing.

Our CNC grinding machines are enabled with a variety of features that include but are not limited to:

- Wheel probe for measurement of grinding wheel dimensions and flange length distance (FLD)

- Automatic tool probe for measuring and transferring tool offset data to the software

- CNC-traveling steady rest for tools with higher length to diameter ratio

- Automatic fire extinguisher for safety

- Pneumatic counterbalance for vertical axis in addition to electromechanical brake on servo motors

- Panel cooler for electrical cabinet

- Automatic workpiece/tool loading through robot or compact loader

- IoT-enabled features for production and maintenance data monitoring

Benefits of Our Tool Grinding Machines

- Menu-driven Software: Our tool grinding machines are easy to use. They have a simple menu that helps you set up and use the machine quickly. This means anyone can learn to use it fast.

- Ease of Maintenance: These machines are easy to take care of. You can get to parts that need fixing without trouble. They don’t need a lot of repairs, so you save money and keep the machine working longer.

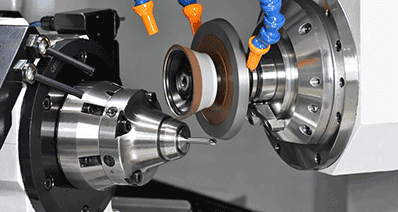

- Multi-Axis: WIDMA’s machines can move in many ways. This lets them make very detailed tools. They can handle many different shapes, which is very useful.

- Precision & Accuracy: WIDMA machines are very exact. They make tools that are just the right size and shape. This is important for making good quality tools.

- Automation: These CNC grinding machines can work on their own. This means they can make a lot of tools without needing a person to watch them all the time. This saves money and makes sure all the tools are of the same good quality.

- Strength & Rigidity: WIDMA machines are strong and don’t shake. This makes them work better and last longer, even when they are used a lot.

- Wide Range of Products: WIDMA has many different machines. This means you can find the right machine for what you need, whether you make a few tools or a lot of them.

- IIoT: WIDMA’s machines can connect to the internet. This lets you check on your machine from far away, fix problems before they get big, and understand how your machine works better. This helps your work go smoothly and keeps you ready for the future.

Menu-driven Software

Ease of Maintenance

Multi Axis

Precision & Accuracy

Automation

Strength & Ridgity

Wide Range of Products

IIoT

Menu-driven Software

Ease of Maintenance

Multi Axis

Precision & Accuracy

Automation

Strength & Ridgity

Wide Range of Products