SPECIAL PURPOSE MACHINES

Indexing Machines

Typical Components

- Cylinder head

- Crank shaft

- Rocker arm

- Connecting rod

- Cylinder Block

- Compressor Crankcase

Valve Seat Machining and

Valve Guide Reaming

Typical Components

Typical Components

- Cylinder head

- Cylinder block

- Crank shaft

- Crank case

- Connecting rod

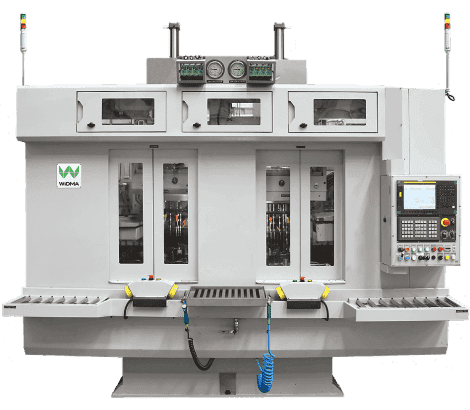

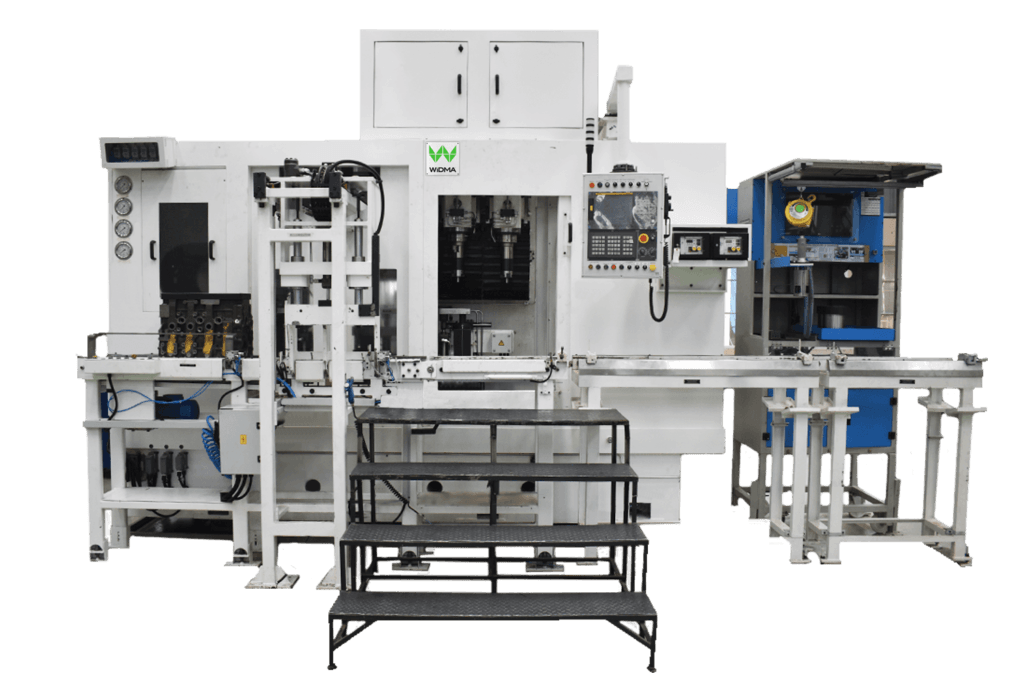

WIDMA’s multi-spindle special purpose machines are built to perform multiple operations simultaneously and offer the best-in-class cycle time. Available in horizontal and vertical configurations, they can be provided with rotary or linear indexing. These machines can be used for operations such as drilling, tapping, rough boring, fine boring, reaming, and spot facing.

Typical Components

- Crankcase and crankcase cover

- Cylinder head

- Cylinder block

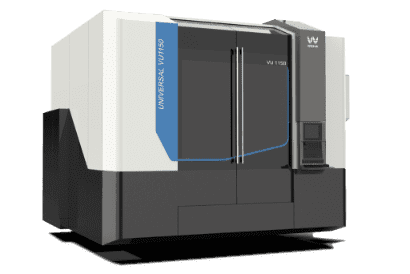

WIDMA facing and centring machines are available in both vertical and horizontal configurations with slides for plunge or traverse milling. They provide accurate centre and face references for further operations like turning and grinding.

• Two spindle machine for smaller shafts

• Four spindle machine for shafts of larger diameter

Typical Components

- Cam shaft

- Crank shaft

- Input shafts

- Output shafts

- Turbine shafts

- Transmission shafts

- Stub axles

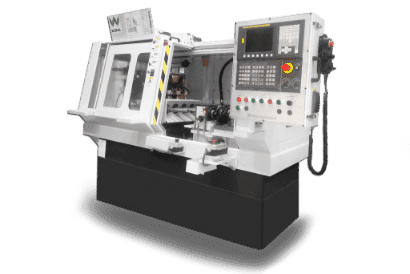

Typical Components

- Cam shaft

- Gear shift drum

- Crank shaft

- CRI nozzle body

- Transmission shaft

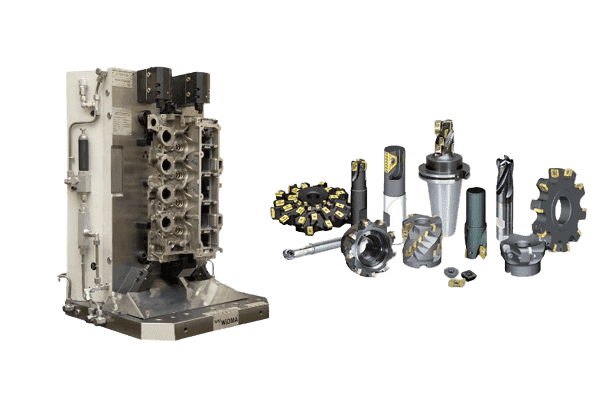

Typical Components

- Cylinder block

- Crank case

- Transmission case

- Cylinder head

WIDMA’s finish milling machines are designed to achieve critical accuracies like flatness, surface finish, and milling depth. They are provided with rigid spindle bearings and sufficient power for stability and near-zero vibration. Depending on components and machining complexity, these special purpose machines can be configured in horizontal or vertical configurations.

Typical Components

- Cylinder head

- Cylinder block

- Crank case

- Transmission case