FIXTURES AND TURNKEY SOLUTIONS FOR MACHINING CENTERS

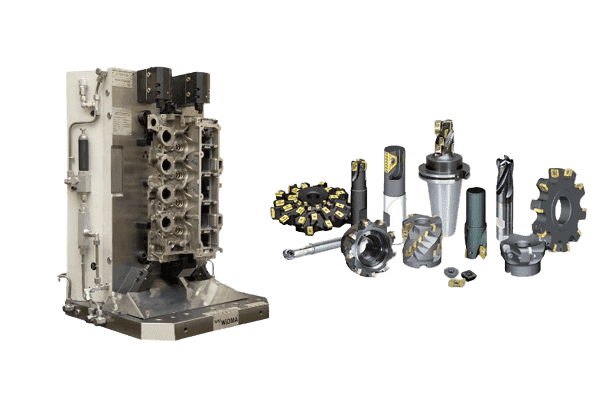

With rich experience in machine building, tooling solutions, and process knowledge, customers turn to us to provide fixtures for their most complex and challenging manufacturing needs. WIDMA has executed over 2500 fixture and tooling turnkey solutions globally on various VMCs and HMCs. Our expertise lies in providing the right tooling solutions for various machining applications of various components and supplying hydraulic, pneumatic, and mechanical fixtures based on the customer’s requirements.

WIDMA provides turnkey fixture solutions, tooling, and other machine accessories for various machining centers across automotive, general engineering, aerospace, farm equipment, and construction machinery-related components. We also support designing the manufacturing process, from the cast to the finished component. The team’s expertise lies in conceptualization, designing, manufacturing, assembling, testing, installation, application support, and proof of component accuracies and cycle time.

Machine Programming

Ease of Maintenance

Precision & Accuracy

Automation

Turnkey Solutions

Strength & Ridgity

Wide Range of Products

IIoT

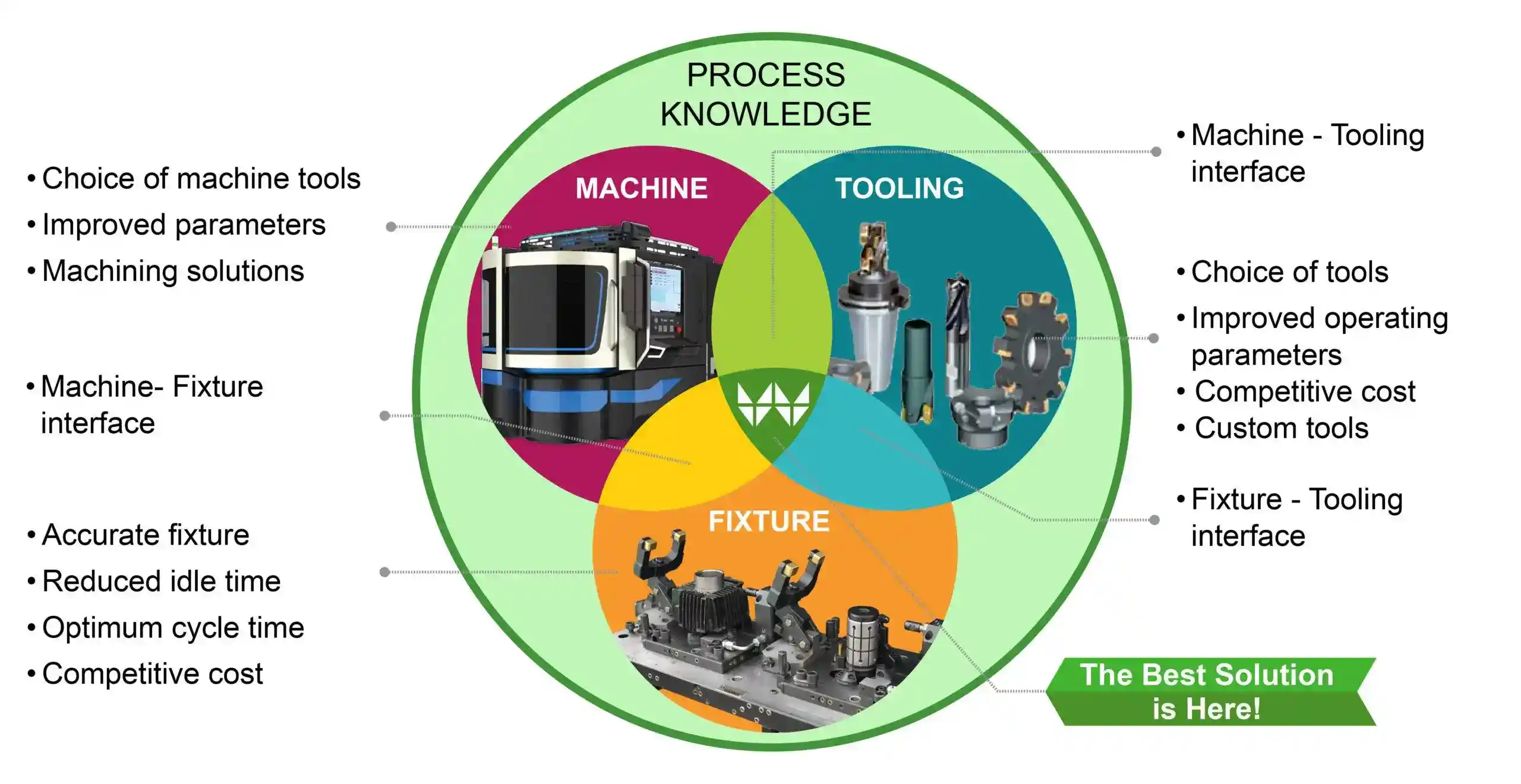

PROCESS ENGINEERING

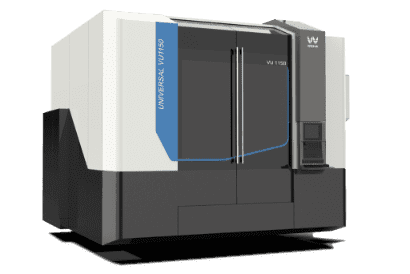

Our team of subject matter experts specializes in planning the manufacturing process for any component, like turnkey fixture solutions, from cast to finish, including detailed study and machining operations identification. Based on the accuracy needs, cycle time estimation and the list of tools needed are prepared, and the cutting parameter is selected in discussion with our parent tooling company, Kennametal. Once these are finalized, the teams identify and select the machinery needed to manufacture these components, including standard machines of other makes.

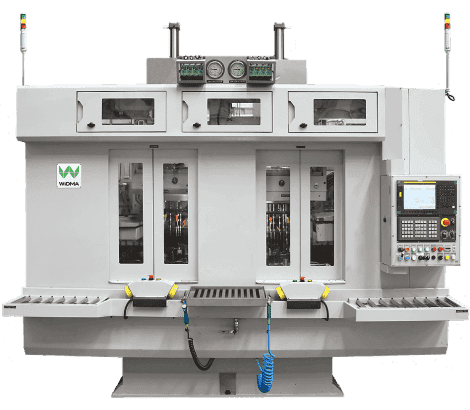

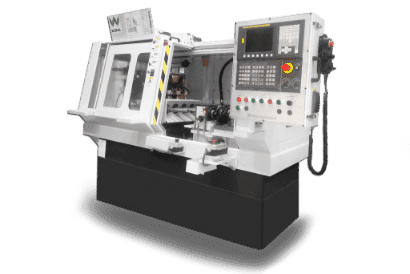

FIXTURES

WIDMA has been a pioneer in providing turnkey fixture solutions to customers across India for more than 2 decades. Our expertise in building machines has translated seamlessly into our fixture-building capabilities, making us the preferred choice for many manufacturing OEMs, their suppliers, and machine tool makers.

Our design team uses the latest 3D software to design and model fixture elements, assemble them virtually, and check for interference to ensure smooth and accurate execution. The team also performs stress analysis of fixture elements such as base plate, clamping elements, and other supporting brackets. It ensures it is designed and optimized to handle the cutting forces easily. We have executed fixtures projects for components of lengths up to 6m.

- In-depth knowledge of process engineering

- Turnkey fixture-tooling solutions in machining centers

- Integration of fixtures with automation

- Additional functionalities such as machine interfacing and machine programming

- Supporting machine accessories such as hydraulic power packs, air-catch sensors, etc.

- Application engineering, prove out, and service support

TOOLING SOLUTIONS

With Kennametal being our parent organization, we have access to the most advanced tools and process database. Tools are customized to enhance their performance parameters, which increase the tool life, leading to increased machine throughput. The tooling team also helps carry out thorough tool inference checks by simulating the actual conditions in 3D to ensure smooth cutting trials at the customer end. We also partner with various other tooling suppliers as per customer-specific requirements.

In addition to the above, WIDMA also supports integration with machining centers for critical machine accessories such as Coolant Systems, Mist Collectors, Pneumatic and Hydraulic Actuation Units, Probing Systems, Panel Coolers, and Conveyor Systems for stand-alone machining centers.

INDUSTRY 4.0 (IOT) SOLUTIONS

WIDMA’s Industry 4.0-ready solutions enable our customers to collect data and monitor various critical parameters through sensors from the fixtures and machine accessories. Parameters such as levels of fluids in coolant and hydraulic systems, pressure, flow, temperature, etc., can be tracked and recorded via I/O-based sensors. This data is then captured and recorded through software integrated throughout the manufacturing production line. WIDMA’s IoT solutions help customers track equipment efficiency and performance parameters. Also, the feedback from machine accessories can help in predictive maintenance, as and when required, thereby ensuring their Overall Equipment Efficiency (OEE).