Multitasking machines are becoming significantly popular in the industry of manufacturing. These CNC machines are basically structured to perform various operations altogether, which eventually helps in improving efficiency, reducing cycle time as well as increasing overall productivity. This following blog will help you in exploring the multiple types of multitasking machines along with their advantages, disadvantages and the future of this technology in the sector of machines.

Types of Multitasking CNC Machines

In the current market there are various types of multitasking machines which are available to give the expected assistance, each one of them has its own set of unique features and capabilities. Some of the most common and popular types are mentioned below:

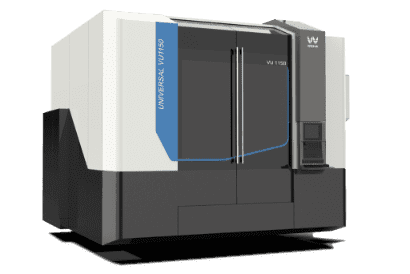

5-Axis Machines

5-axis machines are structured in such a manner that it provides the workpiece to rotate along five axes simultaneously and effectively. This helps the device to reach all sides of the workpiece without the requirement to reposition, so technically that saves time and improves accuracy altogether. These machines are mostly used for machining the complex parts that need multiple operations.

Turn-Mill Centers

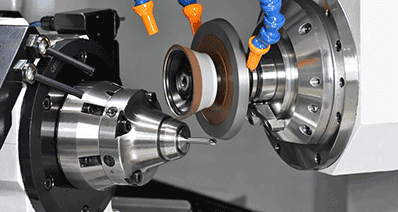

Turn-mill centres include the functionality of a lathe and a milling machine properly into a single unit. This assists the machine to actually perform turning, milling, drilling as well as the other operations on the same workpiece. Turn-mill centres are majorly used for developing the complex parts in a single setup, which eventually helps to reduce cycle time and improve the efficiency.

Swiss-Type Lathes

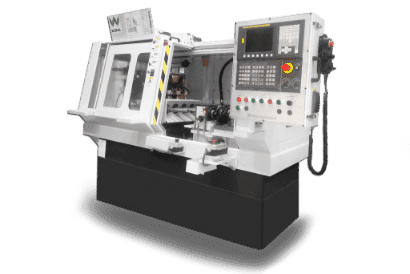

Swiss-type lathes are thoroughly designed for high-precision machining of all the small parts. With the help of sliding headstock, these machines provide the guidance for bushing to support the workpiece which eventually helps to modify accuracy and reduce vibration at the same time. Swiss-type lathes are mainly involved in the production of medical components, aerospace parts along with the other high-precision components.

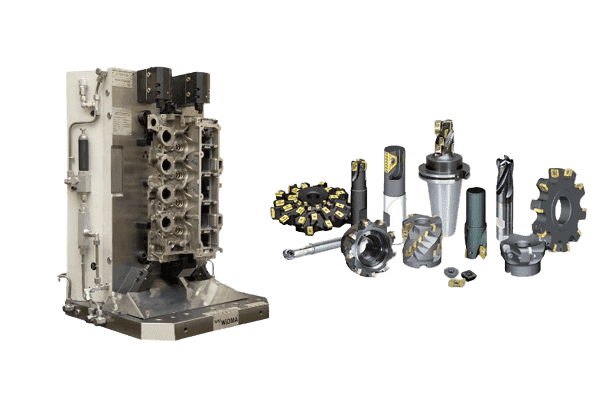

Hybrid Machines

A hybrid machine includes the capabilities of various machine types. For instance, a hybrid machine may join the functionality of a lathe, milling machine as well as a drilling machine into a single unit. This provides an illustration of the machine to present all types of multiple operations on the same workpiece, which in the long term develops the efficiency and reduces cycle time.

Advantages of Multitasking Machines

There are various advantages to using multitasking machines in manufacturing. Below mentioned are majorly one of them:

Better Productivity:

Multitasking machines can actually perform multiple operations simultaneously, which helps to enhance productivity. Additionally, by decreasing the setup and stabilising time, these machines can also produce parts in less time and more proficiently as compared to conventional machines.

Reduced Cycle Time:

Multitasking machines can perform various operations on the similar workpiece, which eventually helps to reduce the entire cycle time.

Improved Accuracy:

Being highly on point, multitasking machines decrease the potential for errors and inconsistencies while producing parts with better tolerances and modified surface finishes.

Greater Flexibility:

The versatility of multitasking machines equip them as an ideal one for producing a huge variety of parts. It also assists to improve flexibility and decrease the requirement for multiple machines.

Improved Quality Control:

As multitasking machines are modified with advanced monitoring and control systems, they permit developed quality control. With the help of tracking the machining process in real-time, these machines can identify and correct all the errors before they become concerning issues.

Disadvantages of Using Multitasking Machines

While there are numerous advantages of using multitasking machines on the other hand there are some disadvantages as well that all the manufacturers must be concerned of, for example:

Increased Complexity:

The concept of multitasking machines are more complicated than conventional machines, moreover the new technological trends are making them more challenging while operating and maintaining at the same time.

Higher Initial Investment:

Companies may have to invest more in multitasking machines because of their higher cost than conventional machines. However, the modified productivity, reduced cycle time along with the improved accuracy provided by these machines can assist to offset the starting cost over the time.

Maintenance and Repair Costs:

It is essential to regularly maintain all the multitasking machines.Thus, these additional costs should be in mind during the time of investments.

Software Compatibility:

Multitasking machines need advanced software in order to operate proficiently. Therefore, it must be fixed that existing software is compatible with all the new machines.

The Future of Multitasking Machines

The usage of multitasking machines is expected to flourish in the upcoming years as manufacturers find ways to enhance efficiency, decrease cycle time as well as increase productivity. Additionally, technological advances are also there to drive the development of current and improved multitasking machines with even better capabilities.

One development area is combining artificial intelligence and machine learning into these machines. This will allow them to not only monitor but also adjust their processes in real-time, improving accuracy and reducing the requirement for human intervention.

Another development corner is the use of 3D printing technology in multitasking machines. This technically allows them to produce complex parts with more accurate proficiency and productivity while opening up to new possibilities in aerospace and medical manufacturing altogether.

As a whole, the future of multitasking machines looks bright along with companies which are continuing to invest in this technology to enhance their manufacturing procedures and develop a competitive landscape in the marketplace.

Conclusion

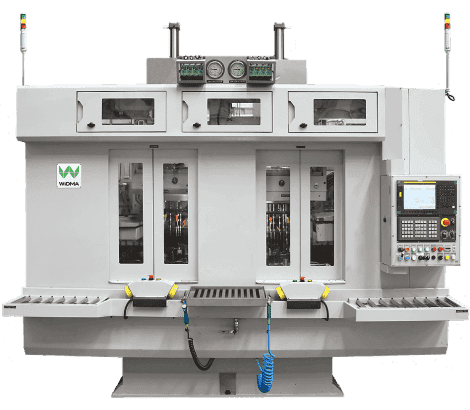

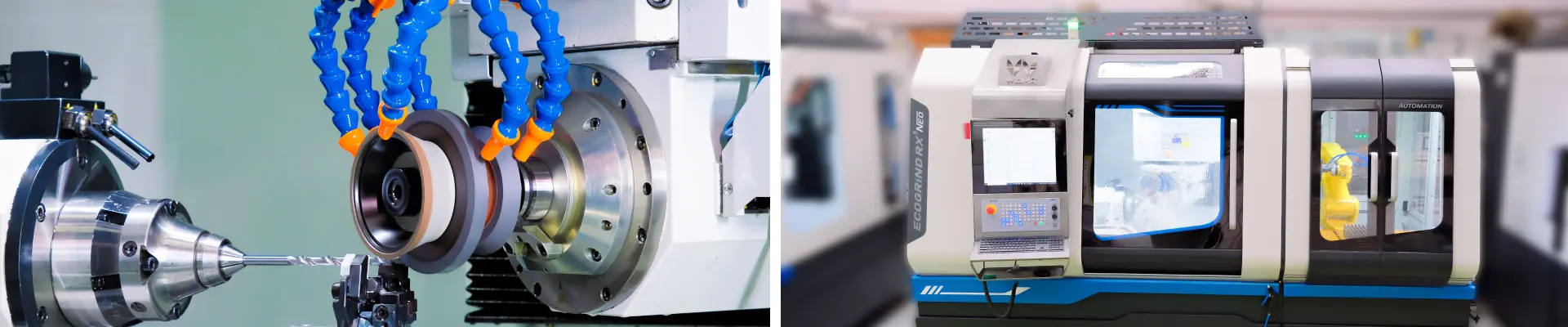

Multitasking machines increase productivity and reduce cycle time along with that it also offers flexibility for the manufacturers. In spite of all the challenges, technological improvements are enhancing these machines’ functionality and capabilities. As the manufacturing industry develops, WIDMA continues to remain at the forefront while delivering solutions to meet all kinds of new demands. With the help of investing in multitasking machines as well as partnering with WIDMA, all the manufacturers can upgrade their operations in order to achieve market success.WIDMA provides the most required and advanced multitasking machines equipped with cutting-edge technology the maximum efficiency, accuracy and also reliability, with that the organisation also assists in training and support for helping in optimization of the entire process.