When engineers talk about gun drilling, they refer to one of the most precise and stable methods of creating long, straight holes in solid materials. Originally developed for manufacturing firearm barrels, the technology has evolved into a highly reliable process used in modern industries like automotive, aerospace, hydraulics, and medical equipment.

This article explores why gun drilling is still the preferred solution for deep hole applications, how it works, and the performance advantages it delivers compared to other drilling methods.

What is Gun Drilling?

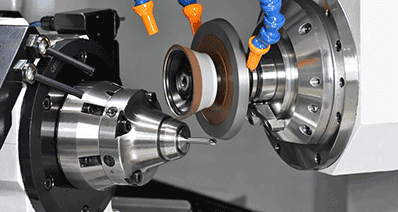

Gun drilling is a specialised machining process used to produce holes with extremely high length-to-diameter ratios, typically greater than 10:1. The process employs a unique single-flute cutting tool that delivers coolant directly to the cutting edge through an internal channel.

The coolant not only lubricates and cools the cutting zone but also carries chips back through a V-shaped groove on the tool’s outer surface. This continuous evacuation of chips prevents clogging, maintains consistent feed pressure, and helps achieve remarkable straightness and surface finish.

How Gun Drilling Works

The process can be simplified into a few controlled steps:

- Setup and alignment – The workpiece is clamped securely, and guide bushings are positioned to ensure accurate tool entry.

- Coolant flow – High-pressure coolant is pumped through the tool’s internal hole.

- Cutting action – The cutting edge gradually removes material while the coolant removes chips through the flute.

- Depth control – Feed rates and spindle speeds are precisely monitored to maintain dimensional accuracy.

- Withdrawal and inspection – After reaching the programmed depth, the tool is withdrawn slowly to prevent scratching or deviation.

The design of the tool, with its single straight flute, carbide tip, and internal coolant delivery, ensures continuous chip evacuation even in holes exceeding several hundred millimetres in depth.

Why Gun Drilling is Preferred for Deep Hole Applications

1. Superior Straightness and Accuracy

Gun drilling delivers outstanding hole straightness because the tool is guided closely at entry, supported continuously by the bushing, and stabilised by coolant pressure. It reduces the risk of drift and achieves positional accuracy that conventional twist drilling cannot match.

2. High-Quality Surface Finish

The constant flow of coolant and controlled cutting geometry produce mirror-like surface finishes, often eliminating the need for secondary honing or reaming.

3. Efficient Chip Evacuation

Chip jamming is a common challenge in deep drilling. The self-flushing design of the gun drill allows chips to exit through the flute under coolant pressure, keeping the cutting zone clean and improving tool life.

4. Consistency Over Long Depths

Because gun drilling maintains a consistent feed and lubrication environment throughout the hole, it produces uniform diameters and finishes even over long depths.

5. Versatility Across Materials

Gun drilling performs well across steels, aluminium, titanium, copper, and even composite materials, making it suitable for varied industrial use cases.

6. Reduced Secondary Operations

The process achieves high roundness and fine finishes directly, often negating the need for additional boring or reaming.

Applications of Gun Drilling

Gun drilling plays a critical role in producing precision components across several industries:

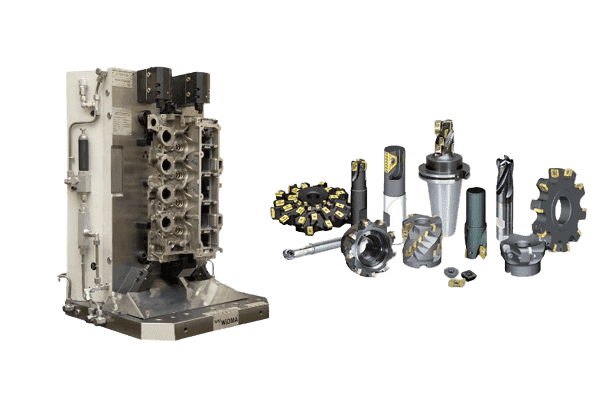

- Automotive: Fuel rails, camshafts, crankshafts, injector bodies

- Aerospace: Landing gear pins, control shafts, turbine components

- Hydraulics: Valve bodies, actuator housings, manifold blocks

- Medical: Surgical instruments, cannulas, and implants

- Tooling & Moulds: Cooling channels in mould inserts and dies

These components demand long, straight bores with tight tolerances, a task perfectly suited for gun drilling machines.

Gun Drilling vs. BTA Drilling

While both are used for deep holes, each method serves different sizes and productivity ranges:

| Feature | Gun Drilling | BTA / STS Drilling |

|---|---|---|

| Diameter Range | 1–40 mm | 20–300 mm |

| Coolant Flow | Through tool centre | Around the tool (external) |

| Chip Removal | Via flute on tool | Through internal tube |

| Hole Accuracy | Very high | High |

| Material Removal Rate | Moderate | High |

| Typical Use | Precision, smaller holes | Large bores, heavy components |

For high-precision applications where finish and straightness matter most, gun drilling remains the first choice.

Optimising Gun Drilling Performance

To maximise tool life and hole quality, manufacturers should focus on:

- Using high-pressure, clean coolant (30–80 bar depending on diameter)

- Ensuring proper guide bush alignment and steady rests

- Selecting carbide-tipped gun drills for wear resistance

- Monitoring feed and speed for different materials

- Implementing in-process measurement and periodic tool checks

These best practices ensure stable performance and reduced downtime during continuous production.

Conclusion

The enduring popularity of gun drilling lies in its precision, reliability, and ability to produce exceptionally deep, straight, and clean holes that other drilling methods can’t match. It is not only a legacy process from the firearms industry but also a modern engineering essential for critical components in automotive, aerospace, medical, and hydraulic systems.

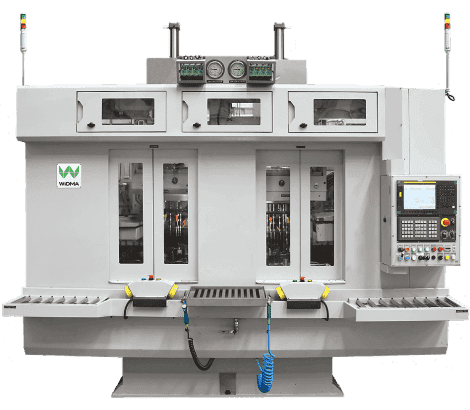

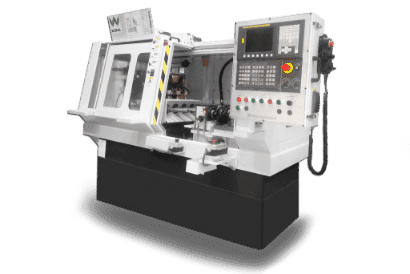

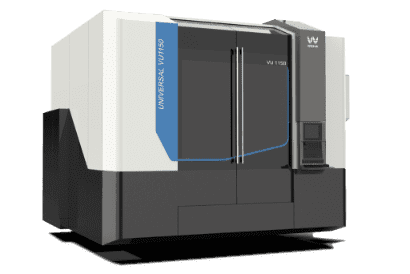

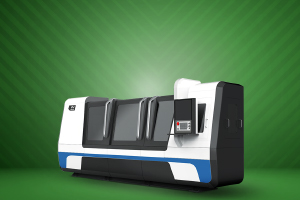

At WIDMA, we design and manufacture advanced gun drilling machines that integrate rigidity, counter-rotation, high-pressure coolant systems, and intelligent controls, enabling manufacturers to achieve greater productivity and accuracy in deep hole operations.

If your production demands flawless bores with consistent tolerances, WIDMA’s gun drilling solutions are engineered to deliver precision that lasts.