In the past decade, India’s manufacturing landscape has undergone a dramatic transformation, one driven by automation, precision, and the adoption of advanced technologies. At the forefront of this change is the CNC machine market in India, marking a decisive shift from conventional machining to computer-controlled precision manufacturing.

Understanding CNC Machines

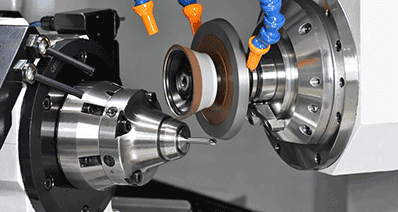

CNC (Computer Numerical Control) machines are automated tools controlled by pre-programmed computer software that dictates the movement of machinery and tools. They play a vital role in industries such as automotive, aerospace, electronics, and heavy engineering, ensuring high levels of accuracy, repeatability, and productivity.

Unlike conventional machines that rely on manual operations, CNC systems automate processes like cutting, drilling, turning, and milling. This not only reduces human error but also allows manufacturers to produce complex parts at high speed and with consistent quality.

CNC Machines: The Backbone of Modern Manufacturing

Today, CNC Machine India’s production represents a major portion of the total machine tools manufactured and sold across the country. As India continues its journey toward becoming a global manufacturing hub, CNC machines have become an essential element of modern production lines.

Among the different categories, Turning and Machining Centers, which include CNC Lathe Machines (Turning Centers) and Machining Centers, are the dominant product types. These machines alone account for more than 60% of total CNC machine production in India, underscoring their widespread adoption across industries that demand high precision and scalability.

This dominance highlights how Indian manufacturers are embracing automation to remain competitive both domestically and internationally. From small-scale workshops to large industrial plants, the presence of CNC machines is now the new standard for quality and efficiency.

The Shift from Conventional to CNC

Over the past few years, Indian manufacturing has undergone a decisive shift from manual operations to automated precision systems. This evolution reflects not just a change in technology but a transformation in mindset — from craftsmanship to consistency, and from human dependence to digital accuracy.

Key highlights of this transition include:

- Rapid market shift: CNC machining centers now hold nearly 68% of the total market share (by value), leaving conventional machines at about 32%.

- Higher productivity: CNC systems enable round-the-clock operation with minimal downtime, drastically improving throughput compared to manual machines.

- Consistent quality: Every component produced maintains the same specifications, eliminating variations caused by human intervention.

- Lower operational costs: Reduced wastage, optimized material use, and predictive maintenance lead to better cost efficiency over time.

- Integration with Industry 4.0: CNC machines are now compatible with IoT, robotics, and data analytics — enabling smarter, interconnected production lines.

- Workforce upskilling: Operators are transitioning from manual machinists to CNC programmers and system managers, marking a skill-driven industrial shift.

This move from conventional to CNC marks a defining moment in the journey of CNC Machine India, setting the foundation for precision-led, globally competitive manufacturing.

Key Factors Driving Growth of CNC Machines in India

- Make in India Initiative

The government’s push to enhance domestic manufacturing capabilities has encouraged investment in high-precision machinery. CNC machines help Indian manufacturers meet global standards and compete with international suppliers. - Rising Demand for Precision Components

Sectors such as automotive, defense, medical equipment, and aerospace require intricate parts that can only be produced through CNC machining. This has significantly boosted demand for advanced turning and milling centers. - Automation and Efficiency

With increasing labor costs and a growing need for standardization, CNC technology offers unmatched speed, accuracy, and cost-effectiveness. - Digital Integration

Modern CNC machines can integrate with CAD/CAM software, robotics, and IoT systems — enabling smart production lines that optimize performance and reduce downtime. - Growing Export Potential

India has emerged as an exporter of CNC machines and precision components, driven by cost competitiveness and improved manufacturing capabilities.

Impact on Indian Manufacturing

The rise of CNC Machine India has revolutionized production processes across sectors. It has enabled manufacturers to reduce dependency on manual operations, minimize human error, and scale operations without compromising on quality.

This has also led to:

- Higher productivity through continuous, automated operation

- Better consistency in large production runs

- Reduced material waste due to precise cutting and machining

- Enhanced competitiveness in global supply chains

As a result, industries that once relied on imports for precision machining now find solutions within India itself. The domestic machine tool ecosystem has strengthened, with several manufacturers innovating to make CNC machines more accessible and cost-effective for small and medium enterprises (SMEs).

The Road Ahead

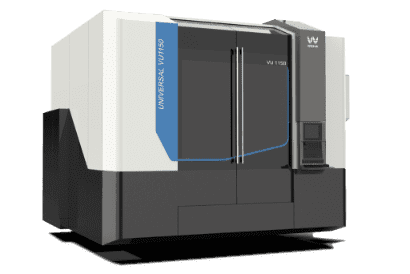

India’s CNC machine industry is poised for continued growth as automation becomes integral to every level of production. The increasing adoption of advanced technologies such as 5-axis machining, robotics-assisted CNC systems, and hybrid manufacturing will further push boundaries.

Moreover, government-backed programs for skill development and digital manufacturing are helping to create a workforce capable of operating and maintaining these sophisticated machines.

As global supply chains seek reliable and efficient partners, India’s CNC manufacturing capability stands out as a symbol of precision, innovation, and resilience.

Bottom Line

The rise of CNC Machine India marks not just an industrial upgrade but a manufacturing revolution. What began as a gradual transition from conventional machines has now evolved into a nationwide movement toward intelligent, automated production.

With nearly 68% of market share now belonging to CNC machining centers and over 60% of production driven by turning and machining centers, India’s manufacturing sector is clearly aligned with global standards.

The message is clear — the future of Indian manufacturing is CNC-powered: precise, productive, and progressive.

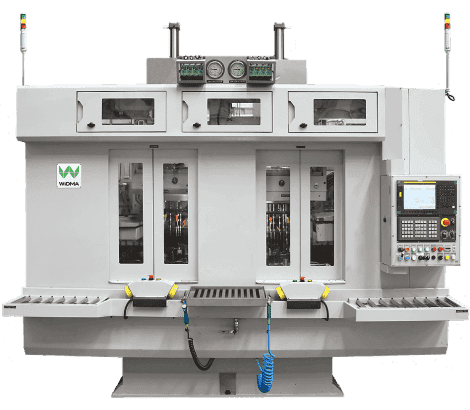

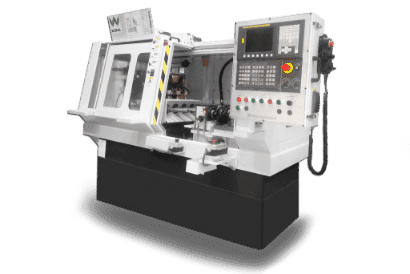

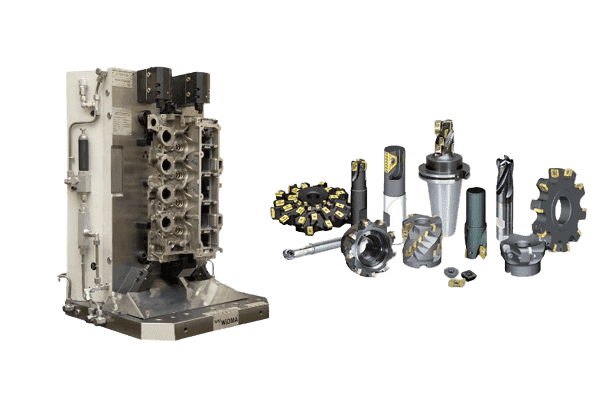

At WIDMA, we design and build high-performance machining solutions for modern production environments. Our expertise spans CNC-based special-purpose machines, deep-hole drilling systems, grinding and turning solutions, as well as precision fixturing and tooling.

Backed by a team of application engineers, we work closely with manufacturers to enhance throughput, improve quality, and reduce the total cost per part across automotive, off-highway, energy, and general engineering sectors.