Manufacturers today operate in environments where precision, consistency and faster turnaround matter more than ever. When exploring automation on the shop floor, two terms come up often: NC and CNC. Both relate to the control of machine tools, but they operate differently and deliver distinct advantages depending on the application. Understanding the Difference Between NC and CNC machines helps manufacturers make informed decisions about productivity, cost and process capability.

What are NC Machines?

NC, short for Numerical Control, refers to machine tools operated by instructions fed into the system through punched cards, tapes or basic control panels. Instead of an operator guiding tool paths manually, the machine follows a sequence of numbers and symbols.

Key characteristics of NC machines

- Programmed Offline: Instructions are prepared in advance using punched tape or cards.

- No On-Machine Editing: Any change requires re-punching or modifying the physical medium.

- Limited Memory: Early NC systems relied on electromechanical storage with fixed capacity.

- Lower Automation: Operators handle setups, offsets and adjustments manually.

NC machines were a major leap from fully manual machining, improving repeatability on similar parts. However, they lack flexibility and computational power compared to modern CNC systems.

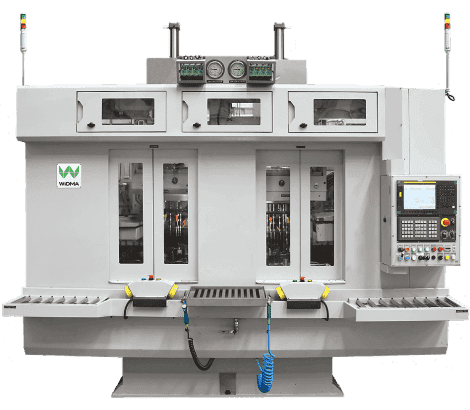

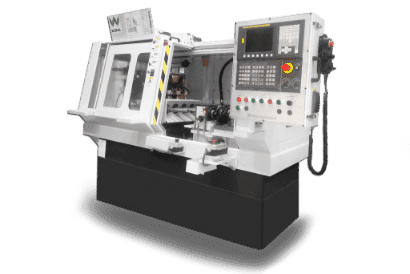

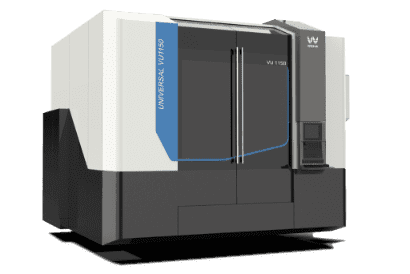

What are CNC Machines?

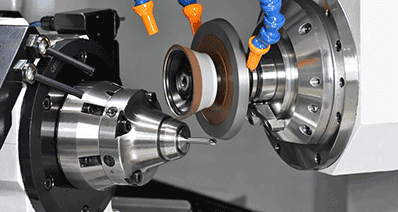

CNC stands for Computer Numerical Control, where a microprocessor interprets digital instructions (commonly in G-code) to control machine axes, spindle speed, feed rate and tool changes. Programs are created using CAD/CAM software and can be edited directly on the controller.

Key characteristics of CNC machines

- Fully Digital Programming: Instructions are coded on computers and stored electronically.

- On-Controller Editing: Operators can correct errors or optimise parameters in seconds.

- High Precision and Repeatability: Servo motors and feedback loops maintain tight control.

- Automation Ready: Tool changers, probes, pallets and sensors reduce human involvement.

CNC systems are now standard across industries where quality and throughput are critical.

Core Difference Between NC and CNC Machines

While they share a common origin, automating tool motion, the following points highlight the fundamental Difference Between NC and CNC technology:

1. Control medium

- NC: Uses punched tapes/cards to feed commands.

- CNC: Uses a microprocessor and digital memory.

2. Programming flexibility

- NC: Programs must be rewritten or punched again for any change.

- CNC: Programs can be edited directly on the controller or in CAD/CAM software.

3. Memory and storage

- NC: Very limited.

- CNC: Large storage, often network-connected, enabling multiple part programs.

4. Accuracy and repeatability

- NC: Good for simple geometry, but sensitive to wear and drift.

- CNC: Servo feedback, closed-loop systems and compensation improve accuracy dramatically.

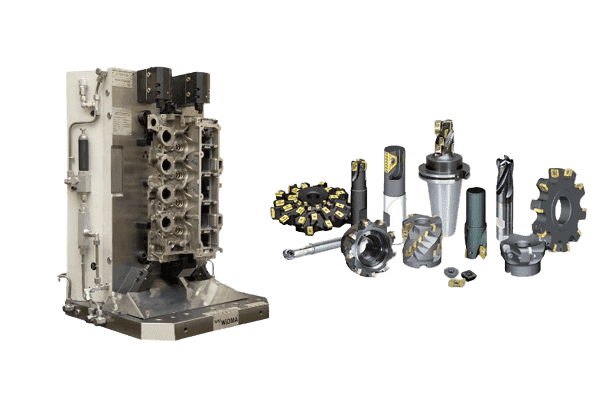

5. Tool changing and automation

- NC: Manual tool changes.

- CNC: Automatic tool changers, probing cycles and tool condition monitoring.

6. Operator skill requirement

- NC: Requires deep knowledge of tapes and sequencing.

- CNC: Requires machine programming and process optimisation skills.

7. Maintenance and downtime

- NC: Mechanical wear on tape readers and components leads to more downtime.

- CNC: Modern diagnostics simplify troubleshooting and maintenance.

Capabilities on the Shop Floor

A practical way to see the Difference Between NC and CNC is in real manufacturing scenarios:

NC systems

- Best for repetitive, standardised parts.

- Limited job change flexibility.

- Ideal when geometry is simple and tolerances are relaxed.

CNC systems

- Handle complex 3D contours, intricate features and tight tolerances.

- Enable frequent changeovers for batch production.

- Provide digital traceability, monitoring and optimisation.

Industries Where CNC Dominates

CNC machines are widely used in:

- Automotive engine components

- Aerospace turbine blades

- Medical implants

- Tooling and die manufacturing

- Off-highway equipment parts

- Precision grinding and turning applications

As demand for accuracy grows, CNC becomes the logical choice.

Productivity Comparison

- Cycle Times: CNC achieves faster cycles through optimised toolpaths.

- Setup Times: Probing and stored offsets reduce setup significantly.

- Quality: Data-driven programming reduces human error and rework.

- Volume: Multi-spindle, special purpose CNC systems multiply output.

An NC machine may deliver acceptable productivity on older line setups, but CNC consistently offers better throughput per square metre of shop floor.

Cost Considerations

NC machines

- Lower upfront cost.

- Limited functionality leads to hidden expenses: labour, rework and machine downtime.

CNC machines

Higher initial investment offset by:

- Faster cycle time

- Lower scrap rates

- Less manual intervention

- Expanded part capabilities

Over time, most manufacturers find CNC delivers a lower cost per part.

Future Trends

Manufacturing is moving deeper into digitalisation:

- Toolpath simulation

- Machine learning-based feed optimisation

- IoT-driven predictive maintenance

- Remote monitoring dashboards

NC machines struggle in this environment due to their analogue framework. CNC thrives because it plugs directly into Industry 4.0 workflows.

Summary: NC vs CNC

| Feature | NC | CNC |

|---|---|---|

| Control Medium | Punched Tape | Microprocessors |

| Editability | Low | High |

| Automation | Limited | Extensive |

| Accuracy | Moderate | High |

| Complexity | Basic Parts | Complex 3D Geometry |

| Data Integration | None | Strong |

The key Difference Between NC and CNC rests in digital capability, speed of adaptation and ease of integration with modern manufacturing systems.

Conclusion

NC machines were a breakthrough in their time, advancing automation beyond manual machining. However, CNC technology has evolved far beyond those early capabilities. With digital programming, high-speed feedback control, automation readiness and integration with software, CNC has become the foundation of modern machining.

Manufacturers looking to improve throughput, flexibility and quality will find the strongest long-term value in CNC solutions.