In modern manufacturing, precision, consistency, and speed are crucial. This is where CNC technology plays a central role. From automotive to aerospace and general engineering, CNC-enabled machines have transformed how components are produced. If you have ever wondered, What is CNC? How does it work? And why do manufacturers rely on it? This guide breaks down the essentials in simple terms.

What is CNC in Manufacturing?

CNC stands for Computer Numerical Control, a system that uses computerised instructions to control the movement of tools and machinery with unmatched precision. Instead of depending on manual input, CNC machines execute programmed commands, usually written in G-code, that dictate every motion, from cutting depth to spindle speed.

In essence, CNC bridges the gap between digital design and physical manufacturing. A designer first creates a 3D model using CAD (Computer-Aided Design) software. This design is then converted into a machine-readable program through CAM (Computer-Aided Manufacturing). The CNC controller reads this program and drives the machine’s motors and actuators to shape, drill, mill, or grind material exactly as designed.

Each CNC system integrates key components:

- Controller Unit: The ‘brain’ that interprets code and manages motion.

- Servo Motors & Drives: Responsible for smooth, accurate movements along multiple axes.

- Feedback Systems: Sensors that ensure real-time accuracy through position feedback.

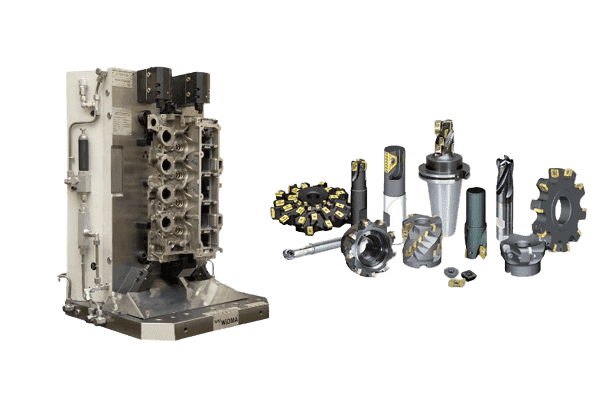

- Tooling & Fixtures: Custom setups that securely hold workpieces during machining.

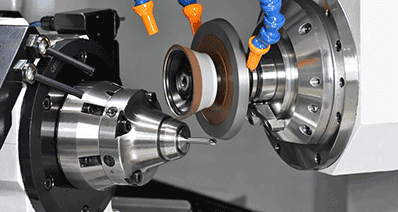

CNC machines perform a wide range of operations, including milling, turning, drilling, tapping, and grinding, all within microns of tolerance. Multi-axis systems (3-, 5-, or even 7-axis) can execute complex operations from multiple directions in a single setup, improving speed, surface finish, and dimensional accuracy.

For manufacturers, this means every part produced, whether it’s the first or the thousandth, meets exact specifications, without variation or rework. CNC has redefined industrial standards of repeatability, efficiency, and safety, making it the foundation of modern precision engineering.

How Does CNC Work?

Though CNC systems can get highly complex, the working principle revolves around a defined digital workflow:

1. Digital Design

A component design is created using CAD (Computer-Aided Design) software. This file defines geometry, dimensions, and material specifications.

2. CAM Programming

The CAD file is converted into CNC-readable code using CAM (Computer-Aided Manufacturing) software. This code instructs the machine on:

- Tool paths

- Cutting speed

- Depth of cut

- Feed rate

- Tool changes

The most commonly used programming language is G-code.

3. Machine Setup

Operators mount raw material, install the correct tool set, and secure workholding fixtures to ensure stability.

4. Automated Machining

Once the program runs, the CNC machine operates autonomously. It moves tools in exact dimensions, often accurate to microns, producing consistent and repeatable results.

5. Inspection

Metrology tools verify that the component matches design specifications, ensuring quality assurance.

Types of CNC Machines Commonly Used

Different machines perform different manufacturing functions. Common examples include:

- CNC Milling Machines: cutting shapes using rotating tools

- CNC Lathes/Turning Centres: producing cylindrical components

- CNC Drilling Machines: precise hole drilling and tapping

- CNC Grinding Machines: achieving exact surface finishes

- CNC EDM: for intricate hard-metal machining

Manufacturers choose a machine type based on application, geometry, and tolerances required.

Why Do Manufacturers Use CNC?

CNC technology has become indispensable to modern manufacturing because it delivers a rare combination of speed, precision, and scalability. It allows industries to maintain high production volumes without compromising on dimensional accuracy, something manual machining cannot achieve consistently.

According to a recent study by Fortune Business Insights, the global CNC (Computer Numerical Control) machine market was valued at USD 95.29 billion in 2024 and is projected to grow from USD 101.22 billion in 2025 to USD 195.59 billion by 2032, registering an impressive CAGR of 9.9%. This growth reflects how industries worldwide are accelerating their shift toward automation, digital manufacturing, and high-precision production.

Key advantages driving this adoption include:

1. High Accuracy

CNC eliminates manual errors and delivers micron-level precision, ideal for engineering-critical components.

2. Consistency and Repeatability

Every part produced matches the previous one, essential for mass production and assembly compatibility.

3. Scalability

Once programmed, CNC can run repeatedly, allowing manufacturers to ramp up production without compromising quality.

4. Complex Geometry

Modern designs include contours, slots, and multi-axis shapes that manual machining cannot handle efficiently.

5. Faster Turnaround

Automation reduces setup time, cutting time, and finishing time, enabling quicker delivery to market.

Industries That Rely on CNC

CNC technology is embraced across sectors such as:

- Automotive

- Electric mobility

- Construction equipment

- Railways

- Aerospace

- General engineering

- Tooling

Each industry values CNC for its reliability, speed, and traceable quality.

CNC vs Manual Machining

| Aspect | CNC Machining | Manual Machining |

|---|---|---|

| Accuracy | Micron-level | Operator-dependent |

| Productivity | High volume | Limited |

| Repeatability | Excellent | Varies |

| Complexity | Advanced geometry | Basic shapes |

| Labour Skill | Programming & setup | Machinist hand-skills |

CNC offers a clear edge where precision and scale matter.

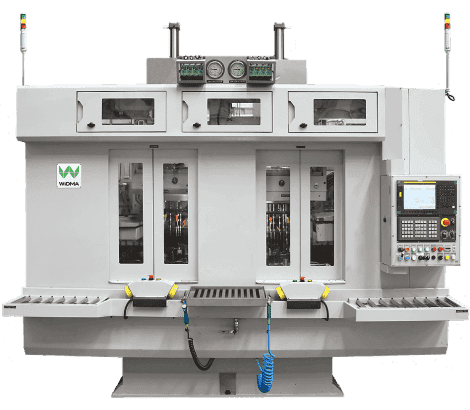

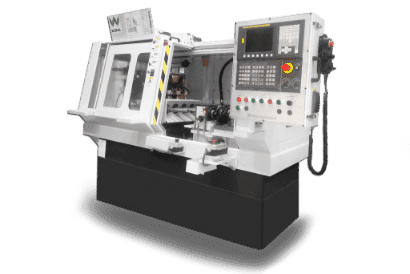

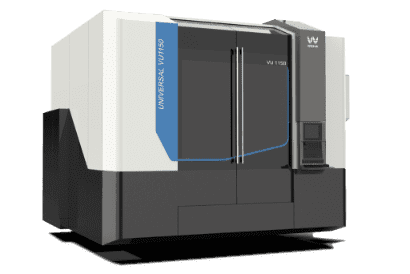

The Role of Advanced CNC Systems at WIDMA

At WIDMA, CNC technology plays a crucial role in delivering Special Purpose Machines (SPMs), multi-spindle drilling systems, and flexible manufacturing solutions. Our CNC-based systems are engineered for:

- High throughput

- Improved cycle time

- Extended tool life

- Stability under industrial loads

- Precise workholding and fixturing

By integrating automation, multi-axis control, and intelligent machining techniques, WIDMA solutions help manufacturers increase output and reduce operational costs.

Future Trends in CNC Manufacturing

As global manufacturing evolves, CNC is advancing through:

- Smart sensors for real-time monitoring

- AI-driven toolpath optimisation

- Hybrid machining (additive + subtractive)

- Digital twins for virtual simulation

- Industrial IoT connectivity

These upgrades are reshaping factories into agile, data-driven systems.

Conclusion

Understanding CNC is the first step toward recognising its importance in modern manufacturing. By combining digital programming with advanced machine tools, CNC systems deliver unmatched precision, repeatability, and speed. From small components to complex assemblies, CNC remains the backbone of scalable production across multiple industries. As technology grows, CNC will continue to drive efficiency and innovation on the shop floor.

WIDMA designs and builds high-performance machining solutions for production environments, including CNC-based special-purpose machines, deep-hole drilling systems, grinding and turning solutions, and fixturing and tooling. Our application engineers partner with manufacturers to improve throughput, quality and total cost per part across automotive, off-highway, energy and general engineering.