Choosing the right hole drilling machine isn’t just about machine specs — it’s about matching the machine to your specific production needs. Whether you’re in automotive, aerospace, or general engineering, the wrong choice can lead to higher downtime, poor hole quality, and unnecessary costs.

Here’s a practical guide to help you make the right decision.

Understand Your Requirements First

Before looking at machines, define the job:

- Material: What are you drilling — steel, cast iron, aluminium, or composites?

- Hole specs: What’s the required diameter, depth, and tolerance?

- Volume: Are you drilling thousands of parts a day, or just a few?

- Precision: Is this a critical application with tight tolerances?

- Setup: Do you need manual control or a CNC-driven process?

Once these are clear, it becomes easier to identify the right category of machine.

Types of Hole Drilling Machines

There’s no one-size-fits-all machine. Here are the main types used across industries:

1.Conventional Drilling Machines

Used in general workshops for simple hole making. Suitable for low-volume or maintenance jobs.

2.Radial Drilling Machines

Good for large, heavy parts where the drill needs to reach over the component. Common in fabrication units.

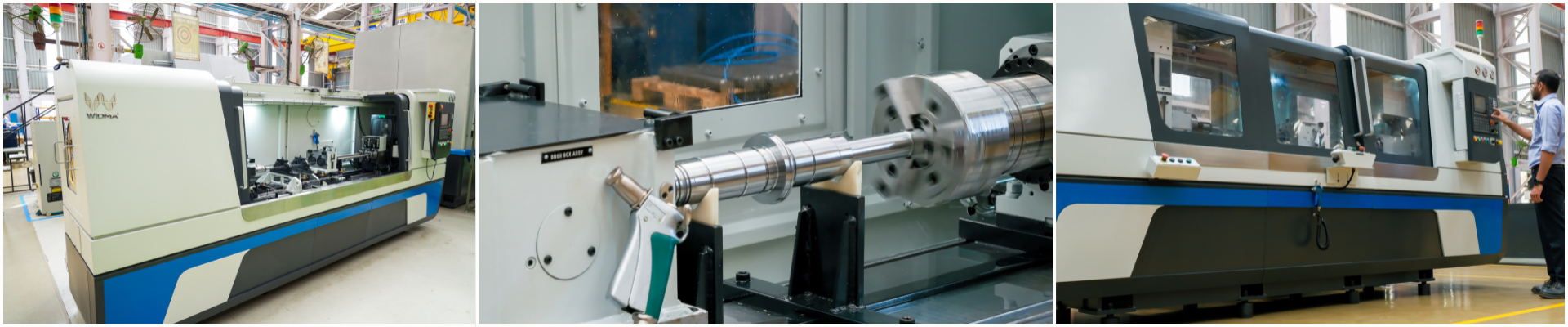

3.CNC Drilling Machines

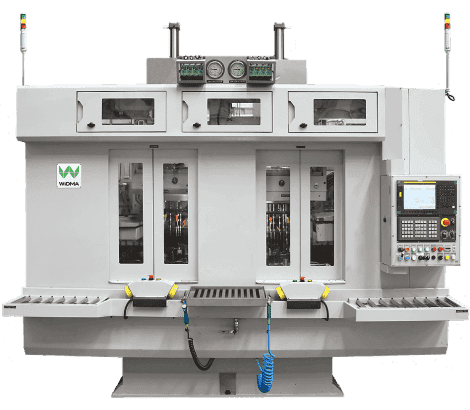

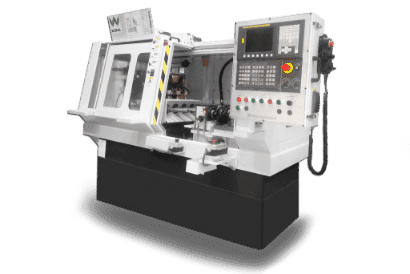

Ideal for high-precision and high-volume applications. Fully programmable and consistent, especially useful in production lines.

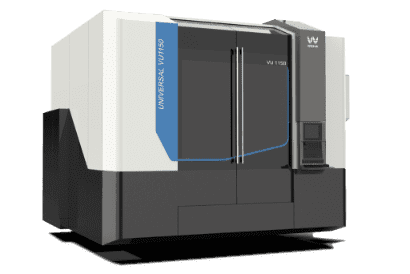

4.Deep Hole Drilling Machines

Special-purpose machines designed for deep, accurate holes (like gundrilling or BTA). Often used in mold, die, and aerospace industries.

5.Portable Magnetic Drills

Used on-site for structural drilling in steel construction or heavy fabrication.

At Widma, we design machines for production environments — where consistency, speed, and accuracy matter most.

What to Look For in a Machine

Once you know the type, look at key performance indicators:

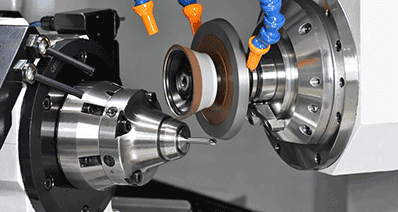

- Spindle Power and Speed Range

This affects cutting ability and finish quality. Harder materials need more torque; smaller holes may require higher RPM. - Rigidity

A rigid structure reduces vibration, improves hole quality, and extends tool life. - Coolant System

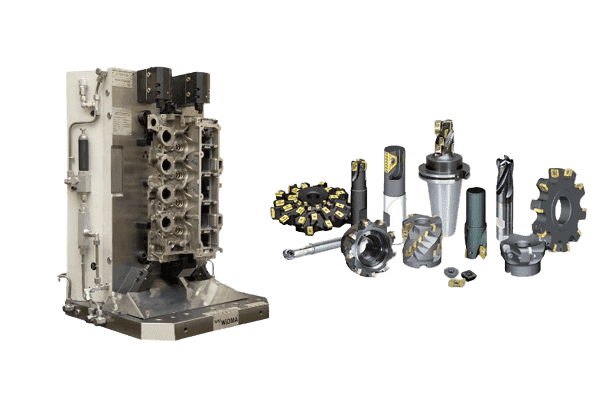

Critical for deep hole drilling. Proper coolant delivery removes heat and chips, and prevents tool breakage. - Tooling and Workholding

A good machine should support reliable fixturing and use standardized tooling systems. - Ease of Integration

If you’re running a modern shopfloor, CNC compatibility and automation readiness are essential.

Consider the Application

Different industries need different things:

- Automotive: High speed, low downtime, consistent hole quality.

- Aerospace: Accuracy, process stability, data traceability.

- Mold and Die: Deep holes with high surface finish requirements.

- General Engineering: Flexibility, ease of operation, and long service life.

Widma offers application-specific solutions across all these segments — built to deliver under tough shopfloor conditions.

Don’t Ignore After-Sales Support

A hole drilling machine is a long-term investment. Downtime due to lack of service support can quickly erase any initial cost savings. Choose a brand with strong service infrastructure, local spares availability, and technical support.

Widma backs its machines with strong post-sales service, application engineering, and maintenance training.

Cost vs. Value

It’s tempting to choose a lower-cost option. But ask: will it hold up in a production environment? Will it keep your tool life high and cycle times low?

Over the machine’s life, what matters is not the price tag — it’s the output quality, reliability, and ease of running.

Final Word

The right hole drilling machine should match your job — not just on paper, but in real-world shopfloor performance. At Widma, we don’t just sell machines; we help you choose the right solution based on your part drawings, batch sizes, and production goals.

If you’re evaluating options, talk to our team. We’ll guide you to the machine that fits — not the one that’s just available.