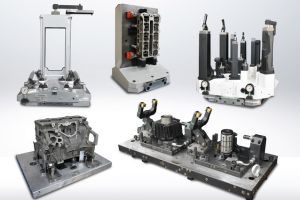

In the complex manufacturing world, fixtures are crucial in ensuring accuracy, efficiency, and stability. However, the design and implementation of fixtures come with their challenges. This blog explores these challenges and highlights how WIDMA’s comprehensive suite of fixtures and turnkey solutions addresses these issues effectively.

Understanding the Challenges of Fixtures

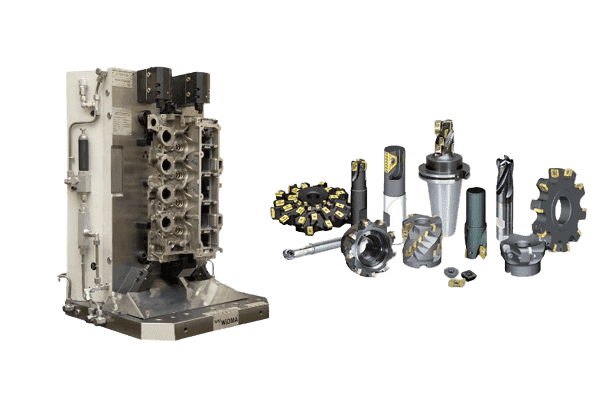

Fixtures are essential in machining and manufacturing processes as they hold and position workpieces securely. Yet, their design and use come with several challenges, read on to know how WIDMA’s solutions addresses them:

-

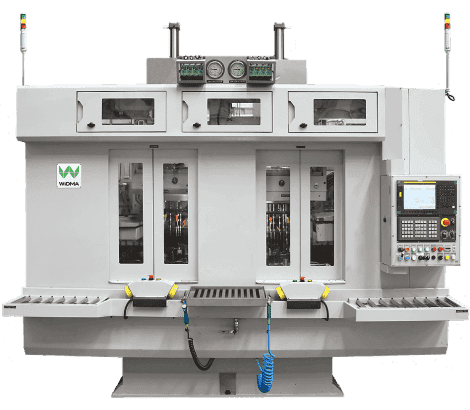

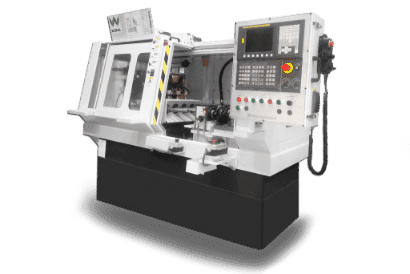

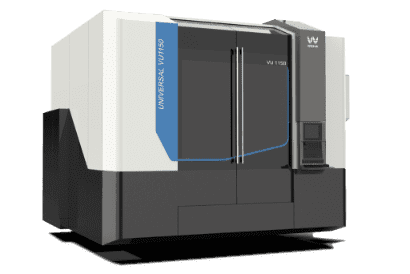

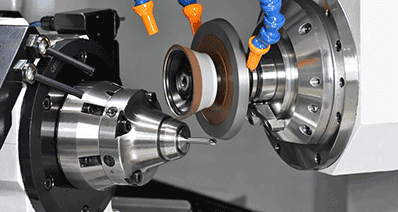

Choice of Machine Tools: WIDMA offers a diverse range of machine tools that can be tailored to specific manufacturing needs. Our expertise ensures that the fixtures are compatible with a wide array of tools, providing flexibility and precision.

-

Improved Parameters: With advanced fixture designs, WIDMA helps in optimizing machining parameters. Our fixtures can be adjusted easily to accommodate different parameters, ensuring that each machining process is performed under optimal conditions.

-

Tailored Machining Solutions: WIDMA provides customized fixtures that are specifically designed for individual machining tasks. This tailored approach ensures that each fixture meets the unique requirements of the job, leading to better performance and quality.

-

Machine Fixture Interface: The precision engineering of WIDMA’s fixtures ensures a seamless interface with machine tools. This stability is crucial for maintaining accuracy and consistency throughout the machining process.

-

Accuracy of Fixtures: WIDMA is known for its high standards in fixture accuracy. Our fixtures are manufactured with meticulous attention to detail, ensuring that they deliver the highest level of precision.

-

Reducing Idle Time: WIDMA’s fixtures are designed for quick and easy setup, which helps in significantly reducing machine idle time. This efficiency translates to increased productivity and cost savings.

-

Optimum Cycle Time: By optimizing fixture design, WIDMA helps manufacturers achieve the shortest possible cycle times. Our solutions focus on reducing machining time while ensuring high-quality output.

-

Machining Tooling Interface: WIDMA provides robust and well-aligned fixtures that enhance the effectiveness of the machining tooling interface. This alignment ensures that the tooling performs optimally, leading to better machining results.

Conclusion

Fixtures are a critical component in the manufacturing process, but their effective implementation can be challenging. WIDMA’s expertise in offering a diverse range of fixtures and turnkey solutions addresses these challenges by providing tailored solutions that enhance precision, reduce idle time, and optimize cycle times. By leveraging WIDMA’s advanced fixtures and machine tools, manufacturers can overcome common fixture-related issues and achieve higher levels of productivity and quality.

For those looking to overcome the hurdles of fixture design and implementation, WIDMA’s innovative solutions offer a path to more efficient and precise manufacturing operations.